About JMS3DPrinting.com online 3D Printing

Background and Design Tools

- Retired mechanical engineer with 40 years of design experience and 15 years as a subject matter expert in Lean Six Sigma manufacturing.

- We strive to ensure our customers get the value they are seeking in a printed 3D part (The screen capture above is lighted holiday lawn ornament.)

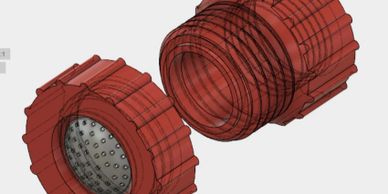

- We own a license to Autodesk Fushion 360 design software because it is capable of creating the kinds of designs our customers ask for.

- We can import STEP files if you already have a preliminary design.

- We can export STEP files to allow suppliers to quote your parts for production using injection molding.

- We have a 3D scanner that can assist in reverse engineering an existing product.

Our 3D Printer

- We use both a Bambu and Afinia H+1 printer.

- We know how to orient the 3D printed part for best strength and appearance and minimal post print cleanup

- 10″ x 8″ x 8″ inch build area (Part can be made in sections if needed)

- Output accurate to within 0.10 mm (4 thousandths of an inch) in the vertical direction and about 0.25 mm (.010 inch) in the x and y direction.

- Material strength varies with print direction.

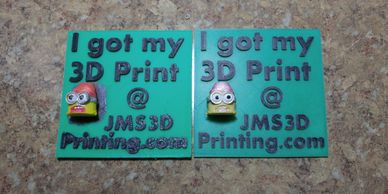

- Multitude of color ABS materials available, including color changing and glow in the dark. See photo below.

- We also have an Emblazer 2 laser cutter that can cut and mark colored acrylic, wood and many other materials.

Why ABS?

- ABS is a common material used for many consumer goods. (e.g. Lego's) Darker colors stand up to the environment, see photo above. Print on right was exposed for a year outdoors compared to the one on the left.

- ABS can be used for flexible parts like snap fits or made stiff by the shape and size.

- PLA is sometimes used by 3D printers but it is not as flexible and will not take high temperatures the way ABS can (124 deg F compared to ABS 179 deg F). The plastic in your car in Florida can exceed 124 deg F on a hot summer day.